Luke Cahill

Is your handrail up to code? Handrail Compliance Guide Made Easy

Reading Time: 10 minutes and 8 seconds

Ensuring your handrails are up to code is crucial for home and business safety. Following the right standards means everyone can use your spaces safely and comfortably. We’ve been doing this for years as a steel fabricator and handrail and balustrades expert, and know all the ins and outs. I remember one project where a simple handrail adjustment prevented a potentially serious fall. Let us help you navigate the essentials of handrail compliance!

Table of Contents

Why handrail compliance is important?

Let me tell you about a local community centre that ran into big trouble because their handrails and balustrades weren’t up to code. They had several minor injuries—trips and falls—because the handrails were either too low or not continuous. These accidents could have been easily avoided by following the right standards, showing just how important proper handrail compliance is.

Here in Australia, we have key standards like AS1657, which deals with fixed platforms, walkways, stairways, and ladders, and AS1428, which is all about design for access and mobility. Knowing and using these standards is essential to keep everyone safe and make sure spaces are accessible for all.

When is a handrail required?

I remember the time I was called to a friend’s new café to help with the final touches. We were setting up the place, and he asked, “Do I really need handrails here?” The answer is yes—handrails are a crucial part of building safety. If you have stairs, ramps, or elevated landings, you’ll likely need handrails. They’re essential for preventing falls and ensuring everyone can move around safely.

Ramps

From my experience, handrails are absolutely necessary if your ramp has been built for public use and when working under the guidelines of the National Construction Code (NCC) . I remember working on a project for a local library where we designed and installed handrails on a ramp to establish a safer entrance with a modern classy design to enhance the building. Without them, it would have continued to be technically a non-compliant entrance to the building .

Stairways

Think about the last time you walked down a set of stairs with a modular and industrial looking handrail that has been chosen as a ( easy installation) – did it look right? My guess would be no especially on a building that is seen by hundreds of people daily. Our architectural DDA compliant handrails will enhance the look of your building and come with a 10 year installation guarantee and warranty.

Landings

For landings more than 1 metre above the ground, handrails are essential. In a renovation we did working alongside the architect and access consultants for a local school, adding handrails to the elevated landings brought peace of mind to both staff and parents, knowing the area was much safer.

What are the handrail codes and standards?

Compliance shouldn’t be a gamble. Handrails are your staircase’s safety net. Let’s ensure your stairs are protected with the right railings. Knowing the handrail codes can help you create a safer environment for your family and guests.

Handrail requirements are outlined in various codes and standards, including the National Construction Code (NCC), ICC guidelines, AS1657, AS1170.1, and AS1428. Ensuring continuous handrails without breaks is essential for safety.

- AS 1428.1:2021 – focuses on design based on people’s movements and abilities, which is perfect for public spaces like pools, schools, and government buildings.

- AS1657:2018 – tailored for industrial settings, catering to maintenance and servicing personnel, but it’s not suitable for areas accessible by the general public.

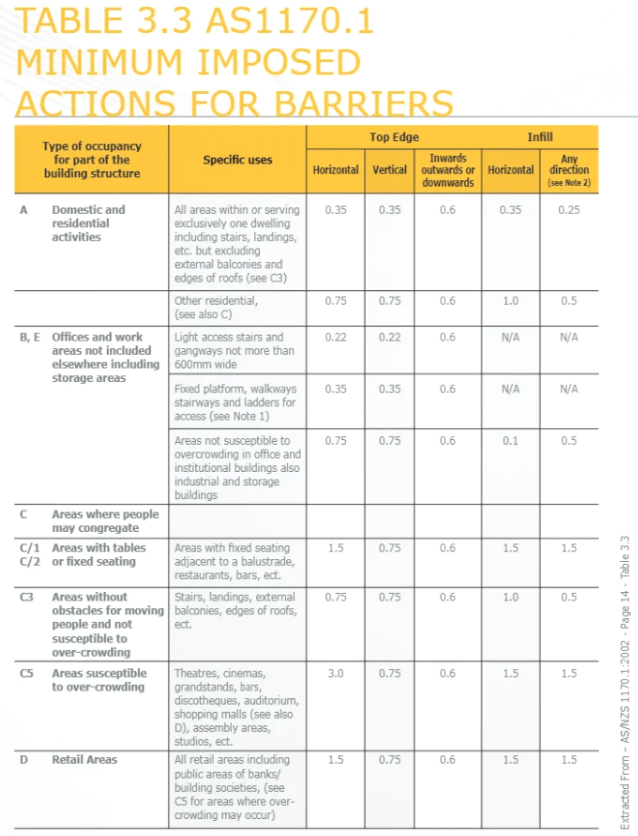

- AS1170.1 – helps us consider the structural design of handrails and balustrades, covering everything from small private balconies to large theatres. This standard ensures that whatever the environment, the handrails can handle the required loads.

In my professional experience, these standards are not just guidelines but critical components of safe building practices. The NCC outlines the fundamental requirements for building safety in Australia, ensuring that all handrails are securely installed. The ICC guidelines are very important for projects with international reach, maintaining consistent safety standards across different regions.

I recall a project at a public library where we adhered to AS1657 for the staff areas and AS1428 for the public spaces. This compliance made the building safer and more accessible for everyone, from young children to the elderly. In our opinion, AS1428 doesn’t just keep people safe—it also adds a touch of class and appeal to buildings, parks, bridges, and other infrastructure with great architectural design.

Minimum Imposed Actions for Barriers (Source: Handrail Compliance Brochure)

How important is handrail height and placement?

I believe handrails are often overlooked, but they’re actually crucial for everyone’s safety. Getting the height and placement right is something I take seriously. Handrails are critical safety components in any setting, from homes to bustling commercial spaces and industrial facilities. Getting the height and placement right isn’t just about convenience; it’s about protecting people. So, let’s talk about why these details matter so much and how to get them right.

Not too long ago, we tackled a project where we saw just how crucial it is to get handrail height and placement spot on. The difference it made was amazing—people felt so much safer and more comfortable. It just goes to show that paying attention to the little things can really have a big impact!

Height Requirements:

| Australian Standard | Location | Height (mm) |

| AS1428 | Stairs & Ramps | 865 – 1000 |

| AS1657 | Industrial areas | 900 – 1100 |

Important Points:

- Handrails should be consistently high throughout, from the top of the stairs to the bottom.

- There must be a clearance of at least 50mm between the handrail and the wall for a secure grip.

- Circular handrails should have a diameter of 30mm to 50mm inches.

- The handrail should extend smoothly, with rounded edges for easy and safe gripping.

The key to safe handrails is consistency. From the many projects I have handled over the years, I’ve seen and experienced how safe and compliant handrails can give people confidence in their surroundings.

What are the best material and style options for handrails?

When designing handrails, it’s not just about making them safe—though that’s incredibly important—it’s also about making them look good and fit in with the rest of the building’s design. I’ve had the chance to work on projects where we’ve had to balance these elements, and it’s always rewarding when we get it right.

Balancing functionality with aesthetics can be a bit of a challenge, but it’s definitely doable. For instance, I remember working on a modern office building where we chose sleek stainless steel handrails. They not only met all the compliance standards but also enhanced the building’s contemporary look. On the other hand, for a cosy residential home, I would recommend installing materials that may be more suited for domestic living to provide the warmth and charm that fit perfectly with the home’s design.

Tips on choosing handrail style and materials:

- The right material makes all the difference. Timber can work wonders in a home setting, while stainless steel shines in modern, commercial spaces.

- Don’t forget—safety standards are there for a reason. Make sure your handrails meet all Australian requirements.

- Your handrails should be more than just functional; they should complement the building’s design.

- Consider the environment—galvanised steel is a great choice for outdoor areas because it’s tough and rust-resistant.

Popular handrail materials:

- Stainless steel

- Powder Coated

- Galvanised steel

- Wrought iron

- Glass

Handrail design requirements:

- One of the most crucial elements in handrail design is height. In Australia, handrails must be installed between 865mm and 1000mm above the floor or the nosing of a stair tread. This specific range isn’t arbitrary—it’s designed to provide optimal support for users of all heights and required for DDA requirements.

- Mechcon is Melbourne’s only company specialising solely in Architectural Handrails with the Disability Discrimination Act (DDA) in mind for all our products and designs.

- Handrails should allow for a firm grip, typically being circular or rectangular. This design consideration may seem minor, but it’s one of those details that can significantly impact user comfort and safety. I remember a project where we had to redesign the handrails after initial feedback from users—switching to a more graspable shape made all the difference.

- Continuity is another key factor. Handrails should run the full length of a stairway or ramp without interruption. This might seem straightforward, but it can be tricky in practice, especially with more complex layouts.

- Handrails need to be strong and durable—they’re something you should be able to rely on for years. At Mechcon, we use top-quality steel to make sure our handrails stand the test of time. I’ve revisited projects years later and found the handrails still in perfect condition, which is exactly what you want for something as important as this.

- Adequate clearance between the handrail and the wall is another detail that’s easy to overlook but critical for usability. It’s these small considerations that make a big difference in how a handrail functions in everyday use.

Top 5 architectural handrail coatings and materials:

Choosing the right materials and coatings for your handrails is crucial for both durability and aesthetics. Here are our top five recommendations:

- Internal Grade Stainless Steel (Grade 304 – Satin Finish) – Ideal for indoor use, Grade 304 stainless steel offers a cost-effective, sleek satin finish (320 grit, no.4). It’s perfect for handrails that need to be both durable and visually appealing.

- External Grade Stainless Steel (Grade 316 – Satin or Mirror Finish) – For outdoor applications, Grade 316 stainless steel is the best choice. Available in satin or mirror finishes, this material is designed to withstand harsh conditions while meeting AS 1170.1 standards.

- Electropolished Stainless Steel (Grade 316) – For superior corrosion resistance and minimal maintenance, opt for electropolished Grade 316 stainless steel. It provides a lasting, bright finish that’s both durable and low-maintenance.

- Hot-Dipped Galvanised Steel Handrails – Hot-dipped galvanised steel is a cost-effective option for robust protection against corrosion, suitable for a variety of profiles and thicknesses.

- Powder-Coated Handrails and Balustrades – Powder coating is ideal for intricate designs and hard-to-paint surfaces, offering UV resistance and a bright, durable finish in a range of colours.

To achieve the best results when working with galvanised metal handrails, proper preparation is crucial. At Mechcon, we recommend a thorough cleaning with a zinc phosphate solution before applying a powder coat in a duplex system. This process ensures maximum adhesion and durability, giving your handrails a long-lasting finish that can withstand the elements.

How does ensuring accessibility with AS1428 make a real difference?

Ensuring your building is accessible is more than just meeting requirements—it’s about making a real impact. I’ve seen this firsthand in projects like the local library where we installed compliant handrails. Before, some patrons found it tough to get around, but after we made the changes, they could navigate the space with ease. Seeing that difference in people’s lives is what makes accessibility so important.

How does ensuring accessibility with AS1428 make a real difference?

When you’re planning a space, making it accessible should be at the top of your list. Here’s what to consider:

- Make sure all paths are smooth and uninterrupted so that everyone, including those with mobility aids, can navigate easily.

- Don’t forget to include handrails on both sides of ramps and stairs. They should be spaced with at least 1000mm of clearance to make them easy to use.

- Ensure there’s enough room for people to turn and move, especially in areas with a lot of foot traffic.

What does AS1428 cover?

AS1428 is the standard that ensures buildings in Australia are accessible to everyone, regardless of their physical abilities. It’s about creating spaces that are not just usable but welcoming. It sets the standards for accessible design, covering everything from the width of pathways to the slip resistance of ramps. These guidelines are crucial for making buildings safe and accessible. It also includes detailed requirements for things like door hardware that’s easy for everyone to use, safe and accessible pathways, and well-designed sanitary facilities. The latest version of AS1428 is a significant step forward, featuring wider handrails and improved stair-nosing design, making buildings substantially more accessible.

As a seasoned architectural handrail steel fabricator, I’ve seen how compliance with AS1428 goes beyond ticking boxes – it’s also about crafting spaces where everyone can move confidently and safely in style . I take pride in shaping steel into handrails that meet legal requirements and enhance the overall design and accessibility of any type of space. When we design and fabricate a handrail that seamlessly blends safety with aesthetics, I know I’m contributing to a more inclusive and modern architectural environment whilst preventing maintenance costs for the life of the Handrail.

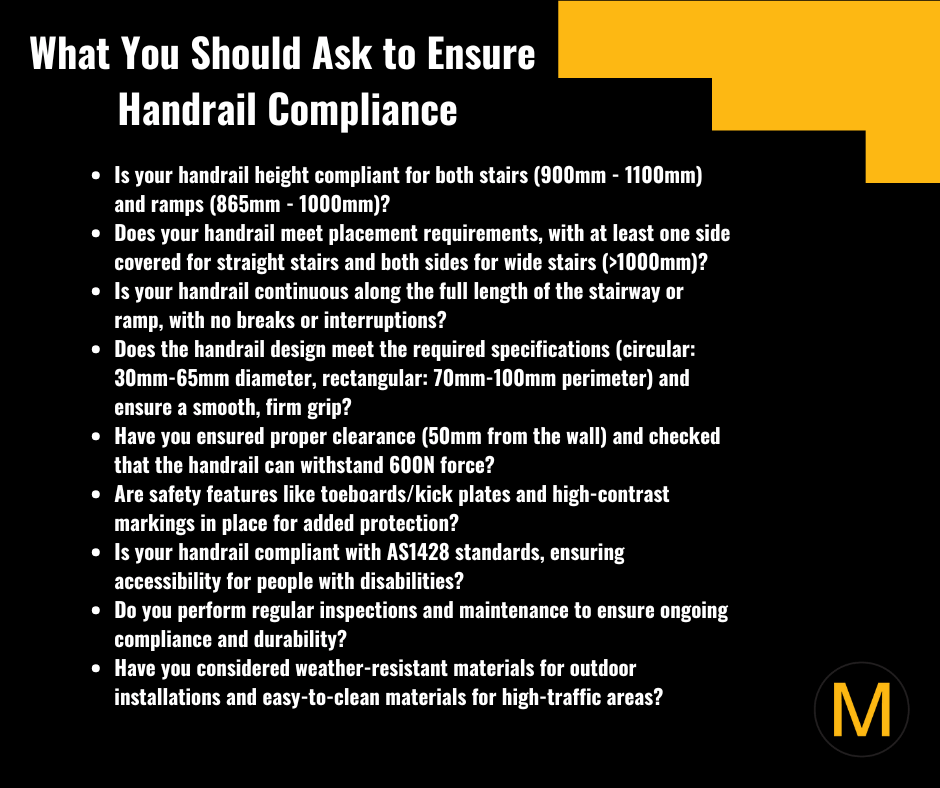

What should you ask yourself to ensure handrail compliance?

Conclusion

Your architectural handrails should do more than just meet standards—they should inspire confidence in the taxpayers and building owners that a cheaper alternative hasn’t been introduced and impacted negatively to a modern building or outdoor space. At Mechcon Welding & Fabrication, we believe that the quick and cheaper marketing for modular handrails is not suitable for most public buildings and outdoor spaces. We are an engineering and construction firm who have chosen solely to specialize in DDA Architectural Handrails since the year 2006,safety and style can go hand in hand, and our team is dedicated to crafting handrails that do just that. We’ve helped countless Melbourne government clients achieve compliance with handrails that are as durable as they are beautiful. Whether it’s a small residential upgrade or a large-scale commercial project, we bring the same level of care and expertise to every job. We understand the nuances of the regulations and the importance of getting it right the first time.

Reach out to Mechcon Welding & Fabrication today—your trusted partner for compliant and stylish handrails and balustrades in Melbourne.

FAQ

Grab rails are usually shorter and often found in bathrooms to help people steady themselves. Handrails are longer and are used on stairs and ramps to help people keep their balance and stay safe. For custom grab rails and handrails, contact Mechcon Welding & Fabrication today!

A balustrade is a whole safety barrier or fence, often made up of many upright posts. A handrail is just the top part that people hold onto when using stairs or ramps.

A graspable handrail follows certain rules about its size and shape. These rules make sure that people can hold onto it firmly and safely. Ensure your handrails are graspable and compliant with Mechcon Welding & Fabrication’s professional handrail and balustrade fabrication services!