STAINLESS STEEL FABRICATION MELBOURNE

Mechcon forms, laser cuts, rolls and fabricates specialised stainless steel products including quality industrial equipment.

- Food Grade Tanks & Vessels

- Pipe & Pressure Vessels

- Ducting Sheet Metal

- Light weight Structures

- Architectural Metal Work Balustrades and Handrails

STAINLESS STEEL FABRICATION GALLERY

STEEL FABRICATION TESTIMONIALS

Have a project you would like to talk about?

Stainless Steel Pipe Fabrication

Technical areas our team has relied upon are things such as food refrigeration, ammonia plant installations for stainless pressure pipe welding, and fabrication AS4041-2006. Mechcon can fulfil all specific requirements when working with high-pressure stainless pipe welding and has executed projects such as:

- Nestle Foods south-east of Melbourne, where they introduced a Quick Freeze process line to their existing plant, requiring small to large-diametre stainless piping to carry ammonia across a 300-metre pipeline throughout the plant

- Mission Foods Australia for the supply, fabrication, and installation of two 15,000-litre stainless steel waste oil tanks and 50-mm food-grade piping driven by an automatic PLC transporting waste oil via electrically actuated valves from inside the plant to external tanks outside the plant, developing a more efficient and safe method of transporting used oil from their industrial cooking vats.

- In conjunction with A.G. Coombs, a new ammonia and propylene glycol refrigeration system was installed at Wholesale Fruit Vegetable & Flower Market, Epping Victoria, one of the largest installations of its kind in Australia. The fabrication of 124 skid-mounted heat exchanger assemblies and 900 mm pipework support structures was manufactured and fabricated by Mechcon Welding and Fabrication. Mechcon achieved zero lost time injuries

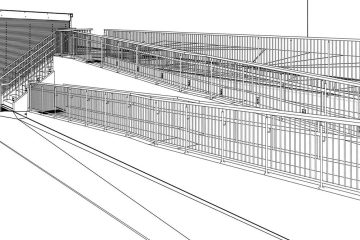

Stainless Steel Handrails Balustrades

Mechcon was selected for the supply, fabrication, and installation of a significant Melbourne centrepiece for the Swan Street Bridge widening project and newly built North, South, East, and West staircases on behalf of Vic Roads and the City of Melbourne, This included 425 metres of handrailing across the bride, marine grade stainless steel handrails on all four staircases leading down to the Yarra River, and bicycle path handrailing. All fixings, materials, and installation methods were strictly to Vic Roads specifications.

Tier 1 Stainless Steel Fabricators

Melbourne Water‘s Eastern Treatment Plant, a 1,100-hectare sewage treatment plant in Bangholme. We were involved with stainless steel gratings and industrial equipment for their pump stations and sludge drying pans for over 6 years. Our workshop is specifically set up for the non-contamination of materials (mild & stainless), which are strictly kept apart through all plate rolling, pipe forming, and fabrication aspects.

Stainless Steel Street Furniture

Mechcon has a 20-year-long close relationship with the leading electropolishing and prestige polishing companies in Melbourne for custom stainless steel street furniture and balustrades.

Custom Stainless Steel Fabrication for Transport and Defence

We have supplied Transport Victoria Tram Stop Platforms with stainless steel protection barriers and handrails for the past 10 years for Yarra Trams. Our long-standing partnership with Yarra Trams is a testament to the quality and reliability of our stainless steel products, ensuring the safety and accessibility of tram stops across Victoria.

Architectural Stainless Steel Fabricators

Our metal fabricators advise leading architects on how to achieve new ways to improve the look of DDA stainless steel handrails to enhance new buildings and infrastructure. Quality industrial stainless-steel equipment is a large part of our business, from manufacturing conveyor systems, and materials handling for food processing to fabricated pharmaceutical equipment, food-grade quality fabrication, and gas purge welding for the dairy industry.

Level Crossing Removal Project Supplier

In the past 5 years, Mechon has supplied quality architectural stainless steel handrails and balustrades to Preston, Bell, Marshall, Geelong South, Rockbank, and Sunshine newly built stations as part of Victoria’s big build and rail crossing removal projects. Tier 1 companies are becoming more and more reliant on Mechcon Welding and Fabrication’s DDA architectural stainless steel handrail expertise. Our approach to modern and classy stainless steel work handrails is more important than ever, as cheap modular overseas-made inferior handrail components are becoming the lazier way to design handrails, which will ultimately create a poor look for architectural and modern buildings and landscapes. Our stainless-steel handrails enhance modern infrastructure and landscapes, which is our ticket to success.

Stainless Steel Fabricators

As experts in many aspects of metal fabrication, including stainless steel fabrication, Mechcon has the experience and know-how to manufacture quality products that will meet your specifications, whether architectural designs, custom fabrications, or custom stainless steel products. When it comes to stainless steel fabrication, stainless steel is often selected as the ideal material for corrosion-resistant steel finished products, it is easily cleaned, durable, and long-lasting.

Have a project you would like to talk about?

DIVERSE APPLICATIONS OF STAINLESS METAL FABRICATION

As a leading stainless steel fabricator in Melbourne, we specialise in producing high-quality stainless steel products for diverse industries. Stainless steel, containing at least 10.5% chromium, is renowned for its corrosion resistance, durability, and aesthetic appeal, making it a versatile material with widespread applications in architecture, medicine, transportation, energy, food and catering.

WHY CHOOSE STAINLESS STEEL PIPING?

One of our core specialities at Mechcon Welding & Fabrication is fabricating high-quality stainless steel pipe. Crafted from a steel alloy containing nickel and chromium, our stainless steel pipes offer unparalleled resistance to oxidation, making them a low-maintenance and durable solution for a variety of applications, including high-temperature and chemical-intensive environments, food, beverage, and pharmaceutical processing, and fluid and gas transport systems.

Stainless steel is a highly versatile material that can be seamlessly integrated into a diverse array of indoor and outdoor applications. By choosing Mechcon’s stainless steel piping, you’ll enjoy a multitude of benefits, including:

-Lightweight yet durable construction

-Long-lasting performance with a lifespan of over 50 years

-Exceptional handling of high-flow rates

-Easy machinability and scratch resistance

-Superior sanitisation and low-maintenance requirements

-Unparalleled corrosion resistance, even in harsh environments

-Eco-friendly recyclability

Our stainless steel pipes are manufactured using advanced welding or extrusion techniques, ensuring a seamless and robust construction that meets the strictest industry standards.

PRECISION-ENGINEERED WELDED AND SEAMLESS STAINLESS STEEL PIPES

At Mechcon, we specialise in the fabrication of welded stainless steel pipes that adhere to the stringent ASTM A-312 and ASME SA-312 standards. Offered in the popular 304/L and 316/L grades, our welded stainless steel pipes range in size from 1/8″ nominal to a robust 24″ nominal, ensuring we have the perfect solution for your project requirements.

In addition to our welded offerings, Mechcon also provides seamless stainless steel pipes manufactured to the ASTM A-312 standard. Available in the 304/L and 316/L grades, our seamless stainless steel pipes cover a versatile size range, from 1/8″ to 8″ nominal, catering to a wide array of applications.

COMPREHENSIVE STAINLESS STEEL FABRICATION INSPECTION AND TESTING PROTOCOLS

At Mechcon, we leave no stone unturned when it comes to ensuring the quality and integrity of our stainless steel fabrications. Our rigorous inspection and testing procedures include, but are not limited to:

-100% Visual Testing (VT)

-Magnetic (MT) and Dye -Penetrant (DPT) Inspections, conducted by third-party experts

-Radiographic (RT) and Ultrasonic (UT) Testing, also performed by third-party specialists

-Ultrasonic Baseline Testing

-Positive Material Identification (PMI) using advanced X-MET 7000 TX and Arc-Met 8000 testers

-Hardness Testing with the Zwick/Roell Microdur MIC 10 BHT and Telebrineller BHT systems

-Hydrostatic and Pneumatic Testing

COMPREHENSIVE STAINLESS STEEL FABRICATION INSPECTION AND TESTING PROTOCOLS

With our unwavering commitment to quality, innovation, and customer satisfaction, We have established ourselves as a trusted name in the stainless steel fabrication industry in Melbourne. Our team of skilled professionals combines technical expertise with a deep understanding of the latest industry trends and best practices, ensuring that every project we undertake exceeds our clients’ expectations.

Whether you require stainless steel pipes for fluid and gas transport or you require customised tube solutions for your manufacturing or construction needs, Mechcon Welding & Fabrication is your go-to partner for durable and versatile stainless steel fabrication solutions.

STAINLESS STEEL FAB FREQUENTLY ASKED QUESTIONS

Have a question that is not listed below, please feel free to Contact Us and we will be more than happy to answer it.

We recommend avoiding harsh abrasives, chlorine-based cleaners, ammonia-containing glass cleaners, and highly acidic foods to preserve the quality and appearance of your stainless steel products. Opt for gentle, non-reactive cleaning solutions and cookware to ensure your stainless steel maintains its brilliant finish and exceptional performance over time.

We emphasise to our clients the importance of maintaining stainless steel time and time again to ensure its longevity and aesthetic quality. Here’s a concise guide for the optimal care of stainless steel:

- Regular Maintenance: Stainless steel should generally be cleaned every three months, but this can vary depending on its environment and usage.

- Exterior Installations: For outdoor applications, align stainless steel cleaning schedules with those of nearby glass, which might range from quarterly to annually, depending on environmental exposure.

- High-Risk Environments: In settings prone to contamination or corrosion—like medical facilities or industrial areas—daily cleaning is advised to maintain hygiene and integrity.

- Cleaning Technique: Use gentle cleaning agents designed for stainless steel and avoid abrasive materials that could scratch the surface. Always clean along the original polish lines to preserve the finish.

Following these guidelines will help maintain the functional and visual quality of stainless steel, ensuring it remains a reliable and attractive material in various applications.

At Mechcon Welding & Fabrication, we specialise in a diverse range of stainless steel fabrication services, including industrial mechanical piping, materials handling systems for the food industry, process piping, high-quality site installation, as well as the design and construction of hoppers, conveyors, architectural handrails, and balustrades.

At Mechcon Welding & Fabrication, we are currently fabricating stainless steel solutions for a variety of sectors, including architecture, medicine, transportation, energy, and food and catering. Each industry benefits from our specialised expertise in delivering high-quality, durable stainless steel products tailored to meet specific functional and aesthetic needs.

Mechcon Welding & Fabrication has been a specialist in stainless steel fabrication for 27 years, initially focusing on the dairy industry and now serving a wide range of industries with expertly crafted stainless steel solutions.

Absolutely! We specialise in custom fabrication and can craft products according to your specific design specifications. Whether you have detailed plans or just an initial concept, our team has the expertise to translate your ideas into durable, high-quality steel or corten products. Some of our offerings include steel stairs, raised garden beds, steel bollards, mezzanine handrails, safety rails, pressure pipes, and more.

When fabricating and welding stainless steel, it is crucial to employ qualified staff with specific technical knowledge of the stainless steel industry, utilise dedicated facilities and workshop spaces to prevent contamination from other materials and implement systems that ensure the proper use of consumables along with efficient methods for polishing and cleaning stainless steel.

Yes, at Mechcon, we stand behind the quality of our fabrication work with comprehensive warranties on both fabrication and installation. Our commitment to excellence ensures that our customers receive durable and reliable stainless steel products that meet the highest standards of craftsmanship and performance.

At Mechcon, we pride ourselves on offering some of the shortest lead times in Australia for DDA-compliant architectural stainless steel handrails. Our efficient processes and skilled team enable us to deliver your stainless steel fabrication project promptly and efficiently, ensuring minimal delays and maximum satisfaction for our customers.

At the heart of our offerings lies the exceptional 300 series grade, with both 304 and 316 stainless steel pipes tailored to meet unique requirements. Type 304 stainless steel is prized for its superior corrosion resistance and ease of sanitisation, making it the ideal choice for food and beverage processing, as well as general building and construction projects. For applications that demand even greater resistance to chemicals and solvents, our 316 stainless steel pipes shine, offering exceptional protection against chloride-induced corrosion and making them the preferred choice for industrial, surgical, and marine environments. Regardless of your needs, Mechcon works closely with clients to deliver customised stainless steel pipe solutions that exceed expectations.

You may assume that steel pipes and tubes are the same. However, while the terms are used interchangeably, it’s critical to know their differences. Steel pipes are measured by their interior diameter (ID) and are primarily used to transport fluids and gases. In contrast, steel tubes are measured by their outside diameter (OD) and wall thickness, and are more commonly used in the construction of parts and structural components.

At Mechcon Welding & Fabrication, our team of experts is well-versed in the nuances of these stainless steel products, enabling us to provide tailored solutions that meet your unique requirements, whether you need high-performance pipes or precision-engineered tubes.

- Chemical processing

- Construction

- Food processing

- Brewing operations

- Pharmaceutical manufacturing

- Textile manufacturing

- Water treatment

- Automotive component manufacturing

- Oil and gas refinement

- Fertiliser and pesticide production

Stainless steel fabrication commonly utilises gauges ranging from 1.6mm to 16mm, depending on the specific project requirements and structural needs. As for finishes, various options are available, including brushed, polished, matte, and satin finishes, each offering distinct aesthetic qualities and corrosion-resistant properties. Our team at Mechcon ensures that you select the most suitable gauge and finish to meet your stainless steel fabrication project’s desired functionality and visual appeal.

We have extensive experience and capability in producing products compliant with AS4041 Stainless Steel Piping Standards. With over 20 years of experience, we have successfully delivered projects adhering to AS4041 requirements, particularly Tier One projects. Rest assured, our team is well-equipped to meet your stainless steel fabrication needs to the highest standards.

While stainless steel fabrication offers versatility and durability, there are some limitations to consider. At Mechcon, we maintain a 10-tonne capacity for fabrication items, ensuring that we can efficiently handle a wide range of projects. However, size and complexity can impact fabrication feasibility, so it’s essential to discuss specific requirements with our team to determine the best approach for your stainless steel fabrication needs.

Have a project you would like to talk about?