Luke Cahill

What is metal fabrication?

Reading Time: 6 minutes and 20 seconds

Metal fabrication is the process that transforms raw metal into strong, functional products we use every day—everything from building frames to household appliances. With our years of experience in this field, we’ve seen firsthand how this craft supports countless industries. In this guide, we’ll take a closer look at the different types of metal fabrication, the core processes involved, and where these techniques are used. By the end, you’ll have a clear understanding of how metal goes from a basic sheet to a reliable part of our modern world.

Table of Contents

Understanding What Metal Fabrication Is

What it is

Metal fabrication is a sophisticated process that turns raw metal materials like sheets, tubes, and rods into essential components for buildings, machinery, and custom products. At Mechcon, we’ve honed our expertise in metal fabrication, knowing that each project’s success depends on precision and a deep understanding of the material’s properties. This involves a series of intricate steps: cutting, bending, and assembling—each requiring a unique set of skills and tools to achieve the desired outcome.

Why it is Important

Without steel fabrication, the structures and tools we use every day wouldn’t exist. It’s not just about building; it’s about building right. The strength, durability, and precision that metal fabrication provides are what allow us to create everything from towering skyscrapers to intricate mechanical parts. As fabricators, we see each project as a chance to contribute something lasting to the world, which is why we approach every piece with a focus on quality and durability.

Where Metal Fab is Used

The impact of metal fabrication can be seen across a wide range of industries. The global steel fabrication market was valued at an astounding $107.6 billion in 2020 and is projected to grow to $135.1 billion by 2025. This growth highlights the critical role that metal fabrication plays in the development and maintenance of infrastructure around the world.

Metal fabrication is typically divided into three primary categories: Industrial, Commercial, and Structural. Each type serves a distinct purpose and requires specialised techniques to achieve the desired results. At Mechcon, our experience spans all three, allowing us to deliver precise and reliable solutions for diverse projects around Melbourne.

Industrial Metal Fabrication

Industrial metal fabrication is designed for projects that demand robust and reliable components, often built to handle high pressures or heavy use. One example of our work in this area involved supporting a high-pressure refrigeration system installation for the Nestle Food Group in Pakenham. This complex job required precision welding and the installation of over 200 metres of refrigeration piping. Each connection had to pass stringent pressure tests, proving that safety and durability are always our top priorities.

Commercial Metal Fabrication

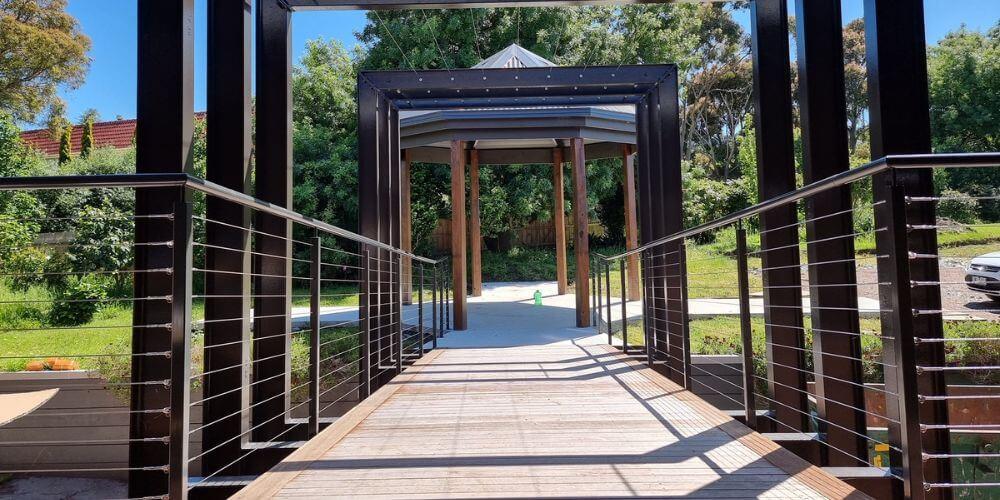

Commercial metal fabrication is often more versatile, combining strength and aesthetic appeal. One of our recent projects involved fabricating and installing a comprehensive metalwork package for a large-scale health club, including handrails, balustrades, and perforated screens. The scope required us to integrate design with functionality, delivering custom solutions that not only met safety requirements but also enhanced the visual appeal of the space. From sleek stainless steel handrails to expansive glass balustrades, commercial projects require a unique balance between form and function.

Structural Metal Fabrication

Structural metal fabrication is essential for large-scale construction projects, providing the foundational elements that support the overall structure. Our experience includes working on Mainfreight’s state-of-the-art distribution warehouse, where we fabricated and installed custom steel brackets, retaining wall handrails, and internal access staircases. These structural components had to be meticulously engineered to ensure the building’s stability and functionality.

The complexity of these projects lies in the need for precise measurement and flawless execution, as even a minor deviation can compromise the integrity of the entire structure. We take a meticulous approach to structural fabrication, ensuring every element is manufactured and installed to the highest standards, so the project can stand the test of time.

What Core Processes are Used

- Cutting: This is the first stage of fabrication, where metal sheets or tubes are shaped into the required dimensions. It can be done using a variety of methods such as sawing, shearing, chiselling, or torching. For more complex or precise shapes, we use CNC (Computer Numerical Control) machines, which employ advanced techniques like laser cutting, plasma cutting, or water jet cutting to achieve a perfect finish. These precision cuts lay the foundation for a smooth fabrication process.

- Bending: After cutting, the next step is bending the metal into specific forms. Whether it’s crafting curves or sharp angles, press brakes and manual or powered hammers are used to shape metal sheets into custom configurations. This is a critical step for creating beams, frames, or brackets that need to fit into a larger structure. The complexity of modern fabrication means even slight deviations in bending can affect the final product’s stability, so we use state-of-the-art press brakes that ensure every bend meets our exacting standards.

- Assembling: Finally, the individual components are brought together through a process called assembling. This step involves welding, riveting, using threaded fasteners, or even further bending techniques like crimping. Our team’s meticulous attention to detail ensures that each joint, seam, or fastening point is secure and aligned correctly, resulting in a strong, cohesive structure that meets both functional and aesthetic requirements.

Our Steel Fabrication Capabilities and Expertise

At Mechcon, we operate a fully equipped steel fabrication workshop, meticulously divided into three specialised zones to cater to a diverse range of project needs. Our Stainless Steel Operations handle architectural and food-grade fabrication, ensuring precise craftsmanship and compliance with industry standards. For mass production, our High-Volume Manufacturing area is designed to efficiently fabricate transport parts at scale. Lastly, our Heavy Fabrication zone is tailored for complex, custom projects, where unique designs and structural components are brought to life.

In addition to our workshop capabilities, we provide a broad range of metal fabrication services that cater to Melbourne’s industrial, commercial, and government sectors. From structural staircases and plant platforms to refrigerated transport components and architectural balustrades, each service is executed with strict adherence to industry standards. Our advanced equipment—such as laser cutting, tube rolling, and NDT services—allows us to take on projects of any scale and deliver results that meet the highest expectations.

Choosing the Right Metal Fabricator

Selecting the right metal fabricator is crucial to ensuring your project’s success, safety, and longevity. At Mechcon, we take pride in offering more than just fabrication services—we bring over 20 years of expertise, advanced capabilities, and a deep understanding of industry standards to every project we undertake.

When you choose Mechcon, you’re partnering with a team that prioritises compliance, quality, and your specific project goals. We hold a NATA Accreditation and adhere to some of the most stringent standards in the industry, including ASME IX, AWS, API, ISO, AS1554, and AS/NZS 3992. Our certifications and proven track record with high-profile clients like VicRoads, Melbourne City Council, and Metro reflect our commitment to delivering solutions that meet the highest benchmarks in safety and performance.

Our Credentials and Capabilities at a Glance

| Certification/Standard | Purpose and Application |

| NATA Accreditation | Ensures compliance with national testing standards, providing quality assurance. |

| ASME IX, AWS, API, ISO Standards | Governs welding, fabrication, and quality control for industrial applications. |

| AS1554 & AS/NZS 3992 | Structural and stainless steel welding standards, ensuring durable and safe outcomes. |

| AS4041 Pressure Piping | Compliance for pressure piping fabrication, critical for safety in industrial plants. |

| AS 1428.1:2009 & BCA 2012 | Standards for accessibility, ideal for handrails and public infrastructure projects. |

| Protective Coating Standards (AS/NZS 2312) | Certified coating systems to safeguard steel components from corrosion and environmental damage. |

Conclusion

For us at Mechcon, metal fabrication is more than just shaping metal—it’s about applying our expertise, precision, and attention to detail to every project. From structural frameworks and custom high-pressure systems to architectural finishes, we approach each job with a commitment to delivering quality results that meet industry standards. With over 20 years of experience and a fully equipped workshop tailored to various needs, we’re proud to provide reliable solutions that consistently stand up to Melbourne’s diverse demands.

FAQ

Yes, we have extensive experience working with government agencies and councils, including Melbourne Water, VicTrack, Arts Centre Melbourne, VicMetro, and VicRoads. Our projects include custom bridge pier forms for VicRoads, weir flow gates for Goulburn-Murray Water, bridge balustrades for Melbourne City Council, and DDA-compliant handrails for Metro railway stations. This track record showcases our commitment to precision, compliance, and delivering high-quality solutions for large-scale public infrastructure projects.

Custom metal fabrication is all about creating unique, purpose-built components that perfectly match your project’s specific requirements. With our experience and technical expertise, we deliver precise, tailored solutions for various industries in Melbourne. Standard metal fabrication, on the other hand, uses predefined templates to produce generic components, which may not fit perfectly with specialised needs. At Mechcon, we’re equipped to handle both, ensuring you get the right solution—whether you need customised precision or standardised efficiency.

At Mechcon, we prioritise quality and compliance by adhering to a range of industry standards and certifications, including NATA Accreditation, ASME IX, AWS, API, AS/NZS, BS, and ISO standards. We also follow the AS1554 series, AS/NZS 3992, AS4041-2006, ASTM A-312, AS 1428.1, and BCA 2012 guidelines. Our expertise ensures we meet specific Australian Standards for safety, structural integrity, and durability in every project, from general fabrication to complex pipework and structural installations.