Steel Fabrication Melbourne

Steel Fabrication – Mechcon specialises in the design fabrication and installation of custom architectural steel fabrication and metal fabrication throughout Melbourne, manufactured locally by our experts.

- Architectural Metal Fabrication

- Architectural Steel Fabrication

- Stainless Steel Welding

- Builders Steel

- Commercial Steel Fabrication

- Resedential Steel Fabrication

- High Rise Builders Work

- Onsite Welding

- Conveyors and Hoppers

- Goverment Steel Fabrication

- Certified Steel

- Steel Batch Numbers Available

- Local Manufacturing in Melbourne Australia

Our Manufacturing Scope varies from supplying high volume truck parts for Australia’s biggest Truck Trailer company through to custom Stainless Steel, Steel, Metal Architectural Fabrication for new and existing buildings in Melbourne.

Mechcon works with quality steel to provide a long-lasting, high-quality end product. We can provide batch numbers and mill certificates upon request, we have systems in place that keep track of mill numbers and heat numbers for our steel.

Mechcon is personally invested in its customers success from beginning to end and will help you evolve and assist to refine your design in an effective way for your project to keep moving and succeed.

Steel Fabrication Testimonials

Our Steel Fabrication Workshop Capabilities

At Mechcon, our workshop is meticulously divided into three specialised areas to ensure precision and quality across all projects:

- Stainless Steel Operations: Dedicated to architectural and food-grade projects, ensuring top-notch craftsmanship and compliance with industry standards.

- High Volume Production Manufacturing: Focused on producing transport parts efficiently and at scale.

- Heavy Fabrication: Tailored for custom fabrication needs, handling complex and unique projects with expertise.

Our Metal Fabrication Services in Melbourne

We offer a comprehensive range of steel fabrication services, all designed to meet the highest industry standards and tailored to your specific needs:

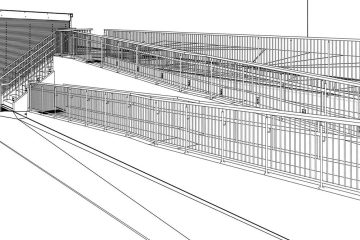

- Structural Staircases: Expertly designed and constructed staircases for residential, commercial, and industrial applications, ensuring safety and durability.

- Architectural Steel Fabrication: Precision fabrication services that enhance the aesthetic and structural integrity of architectural projects.

- Stainless Steel Welding: High-quality welding services for robust and reliable stainless steel structures, perfect for demanding environments.

- Food Grade Processing Equipment: Custom-made equipment for the food processing industry, adhering to strict hygiene and safety standards.

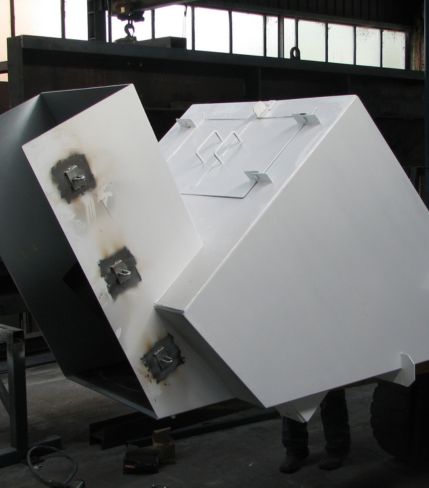

- Conveyors and Hoppers: Efficient and durable material handling solutions designed to optimise your operational workflow.

- Plant Access Platforms: Safe and reliable access platforms tailored to fit your industrial plant, enhance safety and accessibility.

Process Fabrication & Transport

We deliver top-notch steel fabrication services for process fabrication and transport. Here are some of our notable completed projects:

- Rolling Stock Manufacturing Supply Chain: Alstom Dandenong: High-quality fabrication for the rail transport industry, ensuring reliable and durable rolling stock components.

- Refrigerated Road and Rail Transport: MaxiTRANS Ballarat: Expertly crafted refrigerated transport solutions for road and rail, ensuring efficiency and reliability.

- Truck and Trailer Parts: Paccar Bayswater: Precision fabrication of truck and trailer parts that meet the highest standards of quality and performance.

- Custom Chassis Fabrication: Trout River Hallam: Tailor-made chassis fabrication for specialised transport needs, delivering strength and durability.

Top -Tier Architectural Builders Metal Works

At Mechcon, we specialise in high-quality architectural metal works that enhance aesthetics and functionality. Our expertise ensures precision and excellence in every project.

- Spiral Staircases

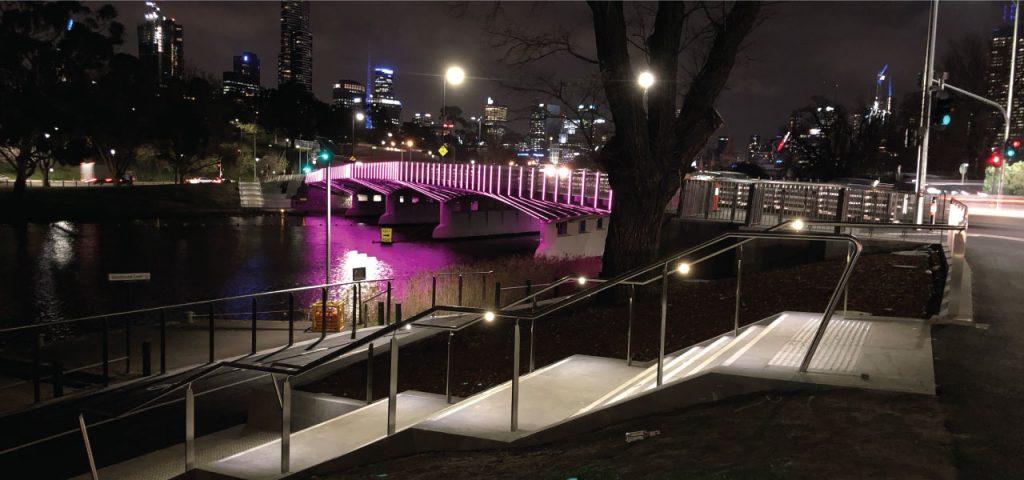

- Balustrades

- Stainless Handrails

- Landscape and Roads Metal Work

Plant & Industrial Steel Fabrication

Our expert team specialises in delivering superior steel fabrication solutions tailored to the unique requirements of industrial plants and facilities. We prioritise robustness, durability, and efficiency in every project, guaranteeing exceptional outcomes that meet and exceed your operational demands.

- Mechanical Plant Platforms

- Mezzanine Access and Railing Systems

- Plant Fabrication / Steam Pipe Fitting & Welding

- Recycling Conveyor Manufacturing and Maintenance

- Loading Dock Barrier Specialists

- Industrial Bollards

Steel Fab for Food Processing & Manufacturing

We specialise in crafting superior stainless steel solutions tailored to meet the exacting standards of the Australian food industry. With a deep commitment to excellence and a keen eye for detail, we deliver products that meet and exceed your expectations.

- Stainless Tank Fabrication and Associated Piping

- Material Handling and Conveyors

- Quality on-site Stainless Steel Welding

With a reputation built on quality, reliability, and a commitment to customer satisfaction, Mechcon is the trusted partner for all your stainless steel fabrication needs in the food processing and manufacturing sectors across Melbourne.

Government Steel Fabrication Infrastructure Projects

At Mechcon, we are happy to showcase our expertise and commitment to quality and precision. Our team of highly skilled steel fabricators and engineers has successfully delivered a diverse range of projects, ensuring compliance with stringent quality standards and regulatory requirements.

- Bridge Pier Forms: VicRoads: Precision-engineered forms for sturdy and reliable bridge construction.

- Weir Flow Gates: Goulburn-Murray Water: Durable flow gates designed for efficient water management.

- Architectural Metal Works Packages: John Holland: Custom metal works enhancing structural aesthetics and functionality.

- Bridge Balustrades: Melbourne City Council: Secure and stylish balustrades for urban bridge projects.

- Railway Station DDA Handrails: Metro: Accessible handrails ensure safety and compliance in public transport.

NDT Workshop Capabilities and Processes

We bring 20 years of expertise in developing weld procedures and quality documentation. Our dedicated team specialises in non-destructive testing (NDT) and project requirements, simplifying the process for clients and engineers.

We specialise in the following standards:

- AS/NZS 1554.5:2004 Structural Steel Welding: Ensuring the highest quality and compliance in structural steel welding.

- AS4041-2006 Pressure Piping: Expertise in pressure piping, meeting strict safety and performance standards.

Trust Mechcon for reliable NDT services and comprehensive support in your welding and fabrication projects.

Protective Coatings Systems for Structural Steel Work and Piping

For over 20 years, Mechcon has been a trusted partner in applying protective coatings for government and tier-one projects. We adhere to AS/NZS 2312 compliance, ensuring high standards in protective coatings and top-quality results for all fabricated items. Our expertise includes:

- Sandblasting (AS 1627.4:2005, SA 2.5 Surface Roughness Comparator): Our most common method for preparing metal surfaces before painting.

- Spark Testing (Holiday Pinhole Detection): Standard procedure for inspecting painted and coated surfaces, especially in government projects.

Comprehensive Workshop Services and Machine Capabilities

At Mechcon, we provide a wide range of workshop services and machine capabilities, ensuring precision and quality for all your fabrication needs. Our state-of-the-art equipment and skilled team can handle various tasks with expertise and efficiency.

- Tube and Pipe Forming, Rolling, and Spiralling: Suitable for all diameters.

- Plate and Sheet Rolling and Folding: Capable of handling thicknesses from 1.6mm to 22mm.

- Laser Cutting: Precision cutting for materials ranging from 2mm to 12mm thick.

- Water Jet Cutting: Efficient cutting for materials with thicknesses from 16mm to 60mm.

- 5.5m Guillotine: Ideal for cutting sheets and plates from 3mm to 12mm thick.

Steel Fabrication Gallery

Steel Fabrication Standards

Steel Fabrication Frequently Asked Questions

Have a question that is not listed below, please feel free to Contact Us and we will be more than happy to answer it.

A. Yes, we do steel fabrication for commercial properties through the areas of Melbourne and Geelong.

We also fabricate for industrial applications. This includes roof plant platforms for food manufacturers, handrails for staircases in multilevel warehouses and numerous other industrial uses.

All of of our steel metal fabrication is compliant to the strictest of Australian standards. Our team of local experts pride themselves on delivering high quality end products as promptly as possible.

A. Yes, we do steel fabrication for domestic homes throughout the greater Melbourne and Geelong area. All our steel fabrication metal is compliant with the strictest of Australian standards. Projects we perform for domestic homes include handrails, balustrades and structural steel.

A. Yes, we do steel fabrication for government and council agencies throughout all of the Melbourne region.

All of our steel metal fabrication is compliant to the strictest of Australian standards. We work closely with councils and government bodies to ensure that the end product meets their requirements.

Throughout our 20 years of experience, we’ve assisted a broad range of projects for councils and government throughout the greater Melbourne area. Projects have included:

- Working with VicRoads and Melbourne City Council on the Swan St Bridge Widening project. 350 lineal metres of marine grade stainless steel handrails were installed.

- Installing galvanised hand rails for the Sunbury and Diggers Rest train station upgrades. These were implemented throughout the station, including on wheelchair access ramps and car parks. New sections were added to meet AS 1428.1 requirements.

- Providing the Arts Centre Melbourne with new compliant handrails and balustrade systems for their external staircases. The previous non-compliant handrails were removed and replaced with new handrails that meet current Australian standards.

A. Yes we do, all manufactured architectural custom, bespoke steel fabrication is compliant to the strictest of Australian standards.

Structural steel projects are another area Mechcon focus on, aiming to deliver high quality infrastructure that is durable, safe and structurally sound.

A. Yes we do, we provide full manufacturing and install of steel metal fabrication. Our team can arrive onsite to install your project. Please speak with our team for a quote on an installation to complement your project design and build.

A. All our steel fabrication is carried out in our Melbourne, Australia factory.

By producing your project in-house, we can focus on ensuring a quality standard is met. Our qualified welders use modern technology and methods to deliver safe welds that hold and last. We strive to meet the strictest Australian standards where required for your project. The highest quality materials are used that are applicable for your project. Another perk of local manufacturing that it reduces transport costs when it comes to delivering and installing the end product.

A. Yes, we often use stainless steel to suit the requirements of our customer’s projects. A fantastic benefit of stainless steel is its ability to endure harsh environments for many years. This makes it great for outdoor conditions or when exposed to salt or chlorine water, like handrails and steps for a pool.

We’ll discuss your project with you in detail to determine the most appropriate metals that will last while also providing the strength needed.

A. Yes we can, as long as it is compliant to the strictest of Australian standards. Please contact our fabrication experts to discuss your plans.

Have a project you would like to talk about?